Shop Talk: The possibilities of printing

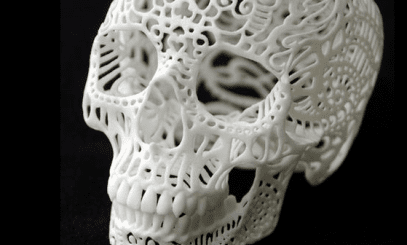

I thought I would share some technology insight, that’s been mulling around in my head for a couple years and has over the past couple years become available to small shops. I’m sure many of you have heard of 3D printing. It’s a process similar to ink jet printing, but using different types of plastics and works with CAD models instead of 2D images.

I was at the Wisconsin Manufacturing and technology Show in Milwaukee this year and was intrigued with the process and thought you might be too. Imagine the possibilities!

Wikipedia definition:

Additive manufacturing or 3D printing is a process of making a three-dimensional solid object of virtually any shape from a digital model. 3D printing is achieved using an additive process, where successive layers of material are laid down in different shapes. 3D printing is also considered distinct from traditional machining techniques, which mostly rely on the removal of material by methods such as cutting or drilling (subtractive processes).

A materials printer usually performs 3D printing using digital technology. The first working 3D printer was created in 1984 by Chuck Hull of 3D Systems Corp. Since the start of the 21st century there has been a large growth in the sales of these machines, and their price has dropped substantially.

The 3D printing technology is used for both prototyping and distributed manufacturing with applications in architecture, engineering, construction (AEC), industrial design, automotive, aerospace, military, engineering, civil engineering, dental and medical industries, biotech (human tissue replacement), fashion, footwear, jewelry, eyewear, education, geographic information systems, food, and many other fields. It has been speculated that 3D printing may become a mass market item because open source 3D printing can easily offset their capital costs by enabling consumers to avoid costs associated with purchasing common household objects.

My thoughts…

I picked up a sample at the show. It is an assembled cresent type wrench. Fully assembled, thumb screw, pin and jaw. Fully functional off the printer. Here’s a quick video of the product: http://youtu.be/gaggOm8Zzko

My understanding is for the clearance of moving parts a dissolvable fluid is dispensed and washed out upon completion, giving the clearance needed.

Give some thought to the idea of being able to purchase a pre-developed model, online of a kitchen appliance and having your local “3D SHOP” print it for you and having it ready for pick up the next day. Inventory? What’s that? Print it as needed or by demand. Shipping? Electronic files go across the country and world far quicker, easier and cheaper than a fully assembled washing machine. In the medical industry think, printed hearts? Joints?…on the spot!

Imagine being able to print replacement parts for a machine or car. Retail stores start to dwindle…”Just Print It” becomes a slogan for the industry.

Currently, It serves as a tool for research and development of Mass produced products but the inception of how else this technology can be used, is endless.

This may be reaching into a personal futuristic vision of what I see, but it is certainly feasible and in due time, we’ll see and hear more great advancements.

Makes one think of the possibilities and incredible technology we already hold.